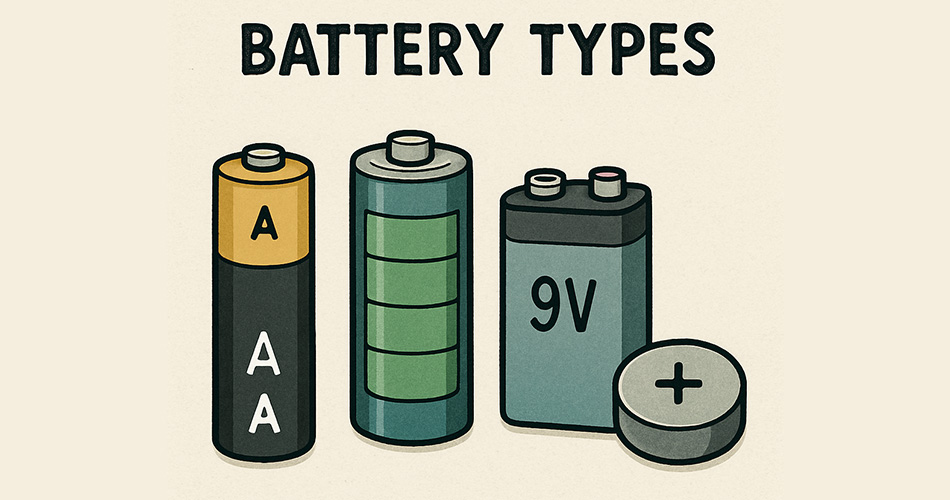

In today's fast-paced world, batteries are essential to power countless devices. From remote controls to flashlights, these small energy sources keep our lives running smoothly. Among the various types of batteries, the 3.2V AA cylindrical battery stands out for its efficiency and wide application. But how are these batteries produced? Let's dive into the battery production process, focusing on a 3.2V AA cylindrical battery factory.

The battery manufacturing industry is a vital part of the global economy. As technology advances, the demand for high-performance batteries increases, pushing manufacturers to innovate and produce more efficient energy solutions.

3.2V AA cylindrical batteries are known for their stable voltage and long-lasting performance. They are commonly used in various gadgets, from household items to industrial tools. Their compact size, combined with a reliable energy output, makes them a popular choice in many sectors.

Creating a 3.2V AA cylindrical battery involves several meticulous steps. Each phase is crucial to ensure the final product's quality and performance.

The production process begins with selecting high-quality raw materials. The primary components include:

Cathode Material: Usually made from lithium iron phosphate (LiFePO4), known for its stability and safety.

Anode Material: Typically composed of graphite, offering excellent conductivity.

Electrolyte: A chemical solution that facilitates ion movement, crucial for battery function.

Once selected, these materials undergo a preparation phase where they are processed to the required purity and consistency.

In this stage, the prepared materials are transformed into electrodes. The cathode and anode materials are coated onto metal foils, often aluminum and copper, respectively. This coating process involves:

Mixing: The active materials are mixed with binders and solvents to form a slurry.

Coating: The slurry is evenly applied onto the metal foils.

Drying: The coated foils are dried to remove any solvents, leaving a solid layer of active material.

Rolling: The dried foils are rolled to achieve the desired thickness and density.

After the electrodes are prepared, they move to the assembly line. Here, the battery cells are constructed through the following steps:

Winding: The anode, separator, and cathode are layered and tightly wound into a cylindrical shape.

Insertion: The wound cell is inserted into a cylindrical metal casing, providing structural integrity.

Electrolyte Filling: The electrolyte is carefully added to the cell, ensuring proper saturation.

Sealing: The cell is sealed to prevent leakage and contamination, using a crimping process.

Once assembled, the batteries undergo a formation process, involving:

Initial Charging: The cell is charged for the first time, activating the chemical reactions.

Cycling: The battery is charged and discharged multiple times to stabilize its performance.

After formation, rigorous testing ensures each battery meets quality standards. This includes:

Capacity Testing: Measuring the battery's energy storage capacity.

Voltage Testing: Ensuring the battery maintains the correct voltage level.

Safety Testing: Checking for any potential hazards, like short circuits or leaks.

Following successful testing, the batteries are packaged for distribution. Proper packaging protects the batteries during transport and storage, ensuring they reach consumers in optimal condition.

The battery manufacturing industry continually evolves, with factories incorporating cutting-edge technologies to enhance production efficiency and battery performance.

Many factories now use automation and robotics to streamline the production process. Automated systems improve precision, reduce human error, and increase output rates.

Environmental concerns drive the industry toward more sustainable practices. Factories aim to reduce waste, recycle materials, and minimize their carbon footprint, contributing to a greener future.

As technology progresses, the demand for efficient, reliable batteries will only grow. The 3.2V AA cylindrical battery is poised to remain a staple in the industry, with ongoing improvements in energy density and safety features.

These batteries are finding new applications beyond traditional devices. From electric vehicles to renewable energy storage, the versatility of 3.2V AA cylindrical batteries continues to expand.

Ongoing research focuses on enhancing battery performance, longevity, and safety. Innovations in materials science and engineering promise exciting advancements in the near future.

In conclusion, the 3.2V AA cylindrical battery factory plays a crucial role in meeting the world's energy needs. Through careful material selection, precise manufacturing processes, and rigorous testing, these factories produce high-quality batteries that power our everyday lives. As the industry advances, we can expect even more efficient and sustainable energy solutions to emerge.

Top 3.2V 26650 Rechargeable Battery Supplier

Reliable 26650 Rechargeable Battery Supplier | Expert Lithium Cells

Efficient 3.2V 26650 Rechargeable Battery Factory

26650 Rechargeable Battery Factory: Manufacturing Benefits

Top 3.2V 26650 Battery Manufacturer: Custom Solutions

Top 26650 Rechargeable Battery Manufacturers

Top 10440 Cylindrical Battery Supplier - Choose Wisely

Reliable 3.2V 10440 Battery Supplier Guide