In the world of portable electronics and renewable energy, lithium-ion batteries stand as a cornerstone, powering everything from small gadgets to electric vehicles. Among these, the 3.2V AA lithium-ion batteries are particularly noteworthy for their reliability and efficiency. But have you ever wondered how these powerful energy sources are manufactured? This article delves into the intricacies of a lithium battery plant, highlighting the key processes involved in producing AA lithium-ion batteries.

Lithium-ion cells are the building blocks of modern batteries. Their popularity stems from their high energy density, minimal memory effect, and slow loss of charge when not in use. These features make them ideal for a wide range of applications, from powering household devices to supporting large-scale renewable energy projects.

High Energy Density: Lithium-ion cells can store a large amount of energy in a relatively small space, making them perfect for compact devices.

Long Lifespan: With proper care, lithium-ion batteries can last for hundreds of charge cycles without significant capacity loss.

Low Maintenance: Unlike other battery types, lithium-ion cells do not require regular maintenance to perform optimally.

Understanding these advantages helps illuminate why the production of AA lithium-ion batteries is crucial for meeting the growing demand for efficient energy solutions.

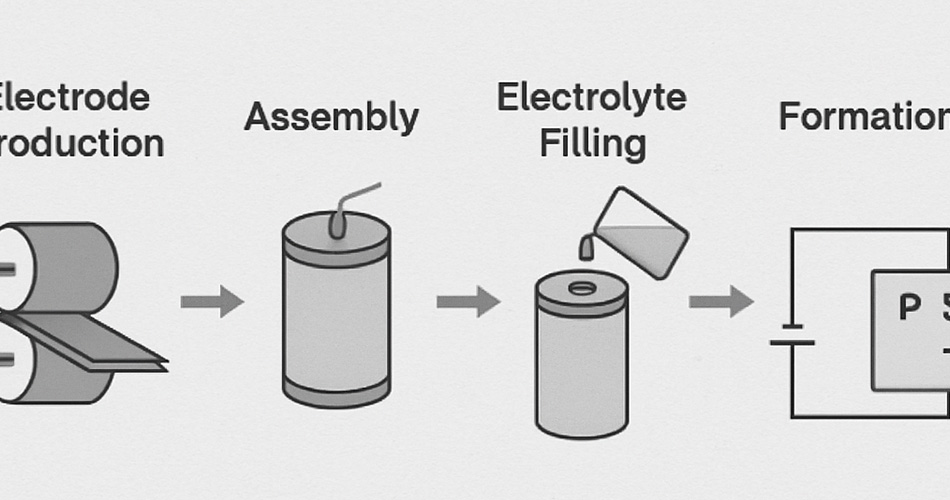

The production of 3.2V AA lithium-ion batteries is a complex process that involves several stages, each critical to ensuring the final product's quality and performance. Let's take a closer look at the key processes inside a lithium battery plant.

The journey begins with sourcing and preparing raw materials. The main components of a lithium-ion cell include:

Cathode Materials: Often made from a lithium metal oxide, these materials are crucial for the battery's energy storage capability.

Anode Materials: Typically composed of graphite, the anode materials play a pivotal role in the battery's charge and discharge cycles.

Electrolyte: This liquid facilitates the movement of lithium ions between the cathode and anode.

Separator: A thin sheet that prevents the cathode and anode from coming into direct contact, avoiding short circuits.

Once the raw materials are prepared, they are processed into electrodes. This involves mixing the cathode and anode materials with binders and solvents to create a slurry. The slurry is then coated onto metal foils, which serve as current collectors. These coated foils are dried and pressed to form thin electrode sheets.

The next step is assembling the battery cells. This is a precise process where the prepared electrodes are stacked or wound together, separated by the electrolyte-soaked separator. The cells are then sealed in a casing to protect them from external elements.

After assembly, the cells undergo a formation process where they are charged and discharged multiple times to activate the materials. This step is crucial for stabilizing the battery's performance. Following formation, the cells are aged for a specific period to ensure they reach their optimal performance levels.

Quality control is vital in a lithium battery plant. Each battery is subjected to rigorous testing to ensure it meets safety and performance standards. This includes checking for capacity, voltage, internal resistance, and overall energy efficiency.

Automation plays a significant role in the efficiency and precision of lithium-ion battery production. Automated systems help streamline processes such as mixing, coating, and assembly, reducing the risk of human error and increasing production rates.

Moreover, advanced robotics and AI-driven quality control systems ensure that each battery meets stringent quality standards, minimizing the chances of defects and ensuring reliability.

The production of lithium-ion batteries also involves careful consideration of environmental impacts. Manufacturers are increasingly adopting sustainable practices, such as:

Recycling Programs: Implementing systems to recycle used batteries and recover valuable materials.

Waste Management: Ensuring proper disposal of hazardous materials to minimize environmental harm.

Energy Efficiency: Optimizing production processes to reduce energy consumption and carbon footprint.

These efforts are crucial for balancing the demand for lithium-ion batteries with environmental stewardship.

As technology advances, the lithium battery plant is poised for significant innovation. Some future trends include:

Solid-State Batteries: Research is underway to develop solid-state batteries that offer higher energy densities and improved safety features.

Sustainable Materials: Scientists are exploring alternatives to traditional materials to reduce reliance on scarce resources and enhance sustainability.

Enhanced Performance: Continuous improvements in battery chemistry and design aim to increase energy capacity and reduce charging times.

These advancements will likely drive the next generation of AA lithium-ion batteries, meeting the ever-growing energy needs of modern consumers.

The production of 3.2V AA lithium-ion batteries is a sophisticated process that combines cutting-edge technology with meticulous quality control. As the demand for efficient and reliable energy solutions continues to rise, the role of lithium battery plants becomes even more critical. By understanding the intricacies of battery manufacturing, we gain a deeper appreciation for the technology that powers our everyday lives and the innovations that lie ahead.

Whether you are a tech enthusiast or a professional in the energy sector, the world of lithium-ion battery production is a testament to human ingenuity and the quest for sustainable energy solutions.

Top 3.2V 26650 Rechargeable Battery Supplier

Reliable 26650 Rechargeable Battery Supplier | Expert Lithium Cells

Efficient 3.2V 26650 Rechargeable Battery Factory

26650 Rechargeable Battery Factory: Manufacturing Benefits

Top 3.2V 26650 Battery Manufacturer: Custom Solutions

Top 26650 Rechargeable Battery Manufacturers

Top 10440 Cylindrical Battery Supplier - Choose Wisely

Reliable 3.2V 10440 Battery Supplier Guide