The demand for portable energy is at an all-time high, and at the forefront of this energy revolution is the lithium-ion battery. These batteries power everything from smartphones to electric vehicles, and their versatility makes them an essential component in our daily lives. Among the various forms of lithium-ion batteries, the AA lithium-ion battery is particularly popular for household devices. In this article, we will explore the role of AA lithium-ion battery manufacturers, their processes, and their impact on modern technology.

Lithium-ion technology has become the gold standard in battery power due to its efficiency and reliability. Unlike traditional batteries, lithium-ion cells offer a higher energy density, which means they can store more energy in a smaller space. This makes them ideal for compact devices like cameras, remote controls, and even some medical devices.

High Energy Density: Lithium-ion batteries can store more energy than other rechargeable batteries, which translates to longer usage times.

Lightweight: Because they can hold a lot of energy, devices powered by lithium-ion batteries are often lighter, which is crucial for portable electronics.

Low Self-Discharge: These batteries hold their charge well, losing only a small percentage of their energy when not in use.

No Memory Effect: Unlike some other rechargeable batteries, lithium-ion batteries do not need to be fully discharged before recharging.

Manufacturers of AA lithium-ion batteries are pivotal in the energy supply chain. They are responsible for creating the cells that power countless devices worldwide. Their expertise in chemistry, engineering, and production ensures that the batteries are both efficient and safe.

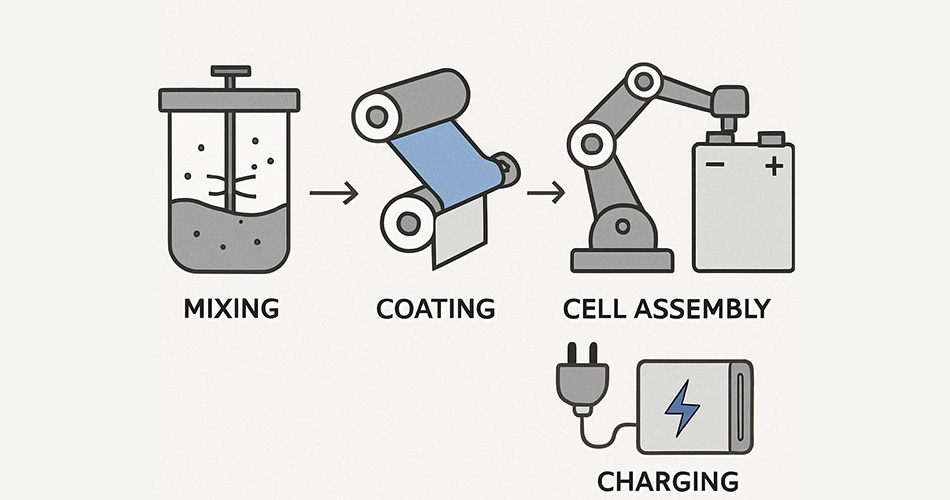

The manufacturing of AA lithium-ion batteries involves several critical steps:

Material Selection: The process begins with selecting the right materials. Lithium-ion batteries are made from a mix of lithium, cobalt, nickel, and other materials. The choice of materials affects the battery's efficiency and safety.

Cell Assembly: The next step is cell assembly. This involves the creation of the anode, cathode, and separator, which are crucial components of the battery. These components are carefully layered to ensure optimal energy flow.

Electrolyte Filling: Once the cells are assembled, they are filled with an electrolyte solution that allows ions to move between the anode and cathode, creating an electric current.

Formation and Aging: After assembly, the batteries undergo a formation process. This involves charging and discharging the battery several times to ensure it operates correctly. Following this, the batteries are aged to assess their long-term stability.

Testing and Quality Control: Before reaching the market, each battery is rigorously tested to ensure it meets safety and performance standards. Quality control is a crucial step to prevent defects that could lead to malfunctions or safety issues.

Despite their advantages, manufacturing lithium-ion batteries presents several challenges:

Material Costs: The raw materials needed for lithium-ion batteries can be expensive, which can drive up costs.

Safety Concerns: Lithium-ion batteries can overheat if not manufactured correctly. Manufacturers must implement stringent safety measures to prevent potential hazards.

Environmental Impact: The production and disposal of lithium-ion batteries can have environmental consequences. Manufacturers are increasingly looking for ways to reduce their carbon footprint.

The lithium-ion battery industry is constantly evolving, with manufacturers investing in research and development to improve battery performance and sustainability.

Recent advancements have focused on increasing the energy density of lithium-ion batteries. This means more power for longer periods, which is particularly important for devices like laptops and electric vehicles.

Another area of innovation is charging speed. Manufacturers are working on technologies that allow batteries to charge faster without affecting their lifespan, which is a significant selling point for consumers.

With growing awareness of environmental issues, manufacturers are exploring more sustainable practices. This includes recycling programs for used batteries and developing production processes that reduce waste and energy consumption.

As the demand for portable and reliable energy solutions grows, the role of AA lithium-ion battery manufacturers becomes increasingly important. These manufacturers are at the cutting edge of technology, continually pushing the boundaries to create more efficient, powerful, and sustainable batteries.

By understanding the intricacies of lithium-ion battery manufacturing, consumers and businesses can better appreciate the technology that powers their daily lives. As innovation continues, we can expect even more exciting developments in this dynamic industry.

In conclusion, AA lithium-ion battery manufacturers are not just producing batteries; they are driving the future of energy. Their work is essential in powering the devices we rely on every day, and their commitment to innovation ensures that we will continue to have reliable energy sources for years to come.

Top 3.2V 26650 Rechargeable Battery Supplier

Reliable 26650 Rechargeable Battery Supplier | Expert Lithium Cells

Efficient 3.2V 26650 Rechargeable Battery Factory

26650 Rechargeable Battery Factory: Manufacturing Benefits

Top 3.2V 26650 Battery Manufacturer: Custom Solutions

Top 26650 Rechargeable Battery Manufacturers

Top 10440 Cylindrical Battery Supplier - Choose Wisely

Reliable 3.2V 10440 Battery Supplier Guide