We are a cutting-edge AA LiFePO4 battery factory solely dedicated to 14500-format lithium iron phosphate (LiFePO4) battery manufacturing. As an intelligent green production hub integrating R&D innovation, large-scale manufacturing, smart quality control, and global distribution, we leverage LiFePO4’s inherent strengths—uncompromising safety, ultra-long cycle life, broad temperature adaptability, and eco-friendliness—to serve B2B clients in industrial IoT, smart automation, outdoor electronics, and precision medical devices worldwide. Our core competitiveness lies in AI-driven AA LiFePO4 production optimization, carbon-neutral manufacturing practices, and scenario-adaptive customization capabilities—establishing us as a trusted partner for brands pursuing reliable, sustainable AA rechargeable battery solutions.

North Smart Mass Production Base (Jiangsu, 28,000㎡): Equipped with 20 AI-integrated automated lines (annual capacity 32 million units) for standard AA LiFePO4 batteries. Adjacent to Ningbo Port (40min logistics radius), the base features digital twin simulation technology to optimize production workflows in real time, achieving a production efficiency of 550 units per minute for bulk orders. It integrates automated warehousing with robotic sorting systems, ensuring 24/7 efficient order fulfillment for large-scale manufacturing clients.

South High-End R&D & Custom Base (Guangdong, 17,000㎡): Home to 7 pilot lines, 3 specialized LiFePO4 labs (material science, performance testing, medical compliance), and an intelligent application validation center. 25min from Shenzhen Port, it focuses on small-batch customization, advanced material R&D (e.g., solid-state electrolyte), and high-precision AA LiFePO4 battery development for medical and industrial critical applications.

Green Material Processing Zone (4,000㎡): Temperature (18±2℃) and humidity (38±5%) controlled Class 800 cleanroom, equipped with closed-loop purification systems for high-purity LiFePO4 cathodes (purity ≥99.7%) and silicon-carbon composite anode modification. Integrated dust recovery systems reduce material waste by 35%, aligning with circular economy principles.

Smart Electrode Manufacturing Zone (9,000㎡): Class 800 cleanroom fitted with Japan’s Toray next-gen precision coating machines (thickness tolerance ±0.008mm) and 3D AI vision inspection systems. Automated calendering and slitting lines are tailored for AA LiFePO4’s optimal electrode ratio (1:1.1 cathode/anode), ensuring uniform current distribution and enhanced energy density in 14500-format cells.

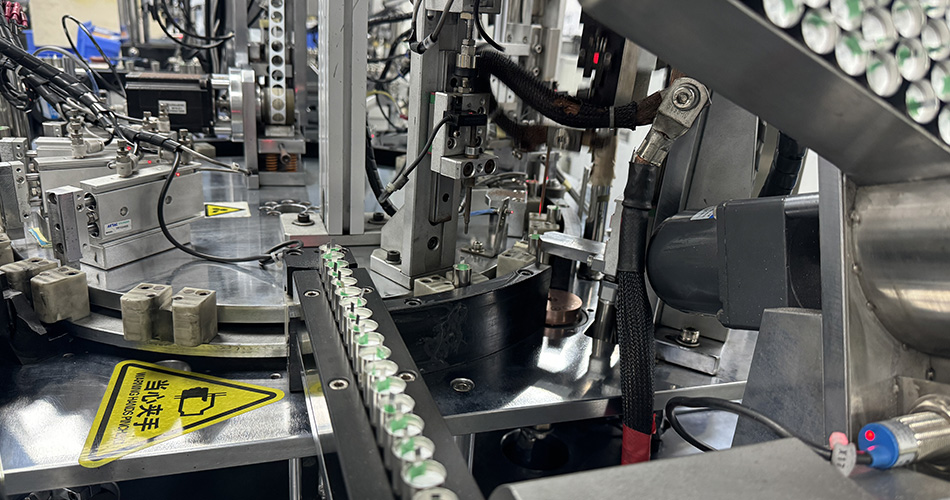

Intelligent Cell Assembly Zone (13,000㎡): 26 AA-optimized production lines featuring precision winding (adaptive tension control ±0.08N), Germany’s Trumpf laser sealing with real-time leak detection (rate ≤5×10⁻⁷ Pa·m³/s), and temperature-controlled electrolyte injection (24±1℃, dosage accuracy ±0.005ml). AGV robots with path optimization algorithms reduce labor intervention by 90%, minimizing production deviations.

Smart Aging & Testing Zone (7,000㎡): Equipped with IoT-connected constant-voltage aging ovens (72-hour adaptive cycle), accelerated cycle life simulators (3000+ cycles), and multi-factor environmental chambers (-45℃~70℃, 0–95% humidity). Each AA LiFePO4 battery undergoes dynamic performance calibration and digital fingerprinting before packaging.

Eco-Packaging & Intelligent Warehousing Zone (12,000㎡): 6,000㎡ humidity-controlled (≤45%) finished product warehouse with AI-managed storage/retrieval system (ASS), supporting 35 million units annual turnover; 6,000㎡ green packaging workshop using recyclable PP materials, offering 120+ packaging specifications (bulk, blister pack, sterile medical packaging, custom branding).

High-Purity LiFePO4 Cathodes: 99.7% pure LiFePO4 with nanoscale particle modification and carbon nanotube coating, enhancing electron conductivity by 40% and ensuring 3000+ charge-discharge cycles with 85% capacity retention.

Silicon-Carbon Composite Anodes: Modified artificial graphite integrated with 10% nano-silicon, increasing AA LiFePO4 battery capacity by 20% (up to 3000mAh) while maintaining structural stability during repeated charge-discharge cycles.

Multi-Functional Electrolyte Formula: Low-temperature additive blend enabling stable discharge at -45℃ (capacity retention ≥75%) and ultra-low self-discharge (≤1%/month), paired with flame-retardant components to enhance safety.

Electrode Coating: Ultrasonic slurry dispersion technology optimized for 14500 size, achieving coating uniformity (thickness variation ≤0.003mm) and strong adhesion (peel strength ≥0.8N/cm) to prevent electrode detachment.

Adaptive Laser Sealing: Welding parameters dynamically adjusted based on cell casing thickness, ensuring hermetic sealing without damaging internal components—extending battery lifespan by 25%.

Smart Formation Aging: Variable current-constant voltage (CC-CV) formation process with AI algorithm optimization, reducing activation time by 30% while stabilizing LiFePO4 crystal structure for consistent batch performance.

Anti-Corrosion & Antibacterial Treatment: 316L stainless steel casing with nickel-plated coating (salt spray test ≥800 hours) and optional ISO 22196 antibacterial coating for medical applications, adapting to harsh industrial and clinical environments.

Specialized R&D Team: 28 engineers (8 PhDs in electrochemistry and material science) dedicated to AA LiFePO4 technology, holding 22 patents (6 international PCT) covering high-capacity material modification, low-temperature performance enhancement, and intelligent manufacturing processes.

Pilot & Rapid Prototyping: South Base’s pilot lines support custom AA LiFePO4 development with a 7–12 day turnaround, offering parameter customization for capacity (1400–3000mAh), discharge rate (0.1C–20C), and special performance requirements (e.g., -50℃ ultra-low temperature, 20C high-rate discharge).

Future Technology Layout: Annual R&D investment of 10% of revenue, focusing on solid-state electrolyte integration for AA LiFePO4 batteries, energy density improvement (target: 450Wh/kg), and wireless charging compatibility.

Raw Material Intelligence Screening: Dual-verification process combining supplier digital audit with on-site laser-induced breakdown spectroscopy (LIBS) testing for LiFePO4 purity (≥99.7%) and anode moisture content (≤0.08%), rejecting non-compliant materials in real time.

In-Line AI Quality Monitoring: 3D vision inspection + machine learning algorithms detect electrode misalignment, coating defects, and sealing irregularities with 99.9% accuracy, triggering automatic production adjustments.

Finished Product Smart Testing: 100% dynamic aging calibration + 10% batch sampling for cycle life, temperature adaptability, and safety tests (short-circuit, overcharge, crush, thermal shock)—compliant with UN38.3, UL 1642, IEC 62133, and GB 31484 standards.

Full-Lifecycle Traceability: Unique QR code + RFID tag for each AA LiFePO4 battery, recording 50+ data points (raw material batches, production parameters, test results, logistics information) with 15-year data retention—supporting one-click traceability via client portal.

Global Certification Portfolio: Products certified with ISO 9001, ISO 14001, ISO 45001, ISO 13485 (medical), CE, RoHS, REACH, and UL 1642. Medical-grade AA LiFePO4 batteries additional hold ISO 10993 biocompatibility certification.

Mass Production Capacity: Annual output of 32 million AA LiFePO4 batteries, supporting bulk orders (100,000–1,000,000 units/month) with 5–10 days lead time and a 99.9% on-time delivery rate.

Customization Services: MOQ 700 units, lead time 2–3 weeks via South Base pilot lines. Customizable parameters include:

Capacity: 1400–3000mAh (nominal voltage 3.2V, inherent to LiFePO4)

Discharge rate: 0.1C–20C (high-rate options for industrial IoT sensors)

Temperature adaptation: -45℃~70℃ (extreme environment customization)

Special features: IP69K waterproof, antibacterial coating, ultra-low self-discharge

Packaging: Bulk, blister pack, sterile medical packaging, custom branding

Capacity Expansion: 5 new AI-integrated lines under construction (commissioned Q3 2025), increasing annual output by 8 million units (total 40 million units/year) to address rising global demand.

Industrial IoT & Automation: AA LiFePO4 batteries with ±0.008V voltage stability and 10–5000Hz vibration resistance, powering smart factory sensor networks, PLC backup systems, and industrial robots. We supply 6 million units annually to global automation leaders, supporting 24/7/365 continuous operation with 99.95% reliability.

Smart City & Low-Power Devices: Ultra-low self-discharge (≤1%/month) AA LiFePO4 batteries with 10–15 year service life, ideal for smart water/gas meters, environmental monitoring terminals, and low-power wide-area network (LPWAN) devices. 4.2 million units/year are shipped to IoT solution providers, reducing maintenance costs by 60%.

Outdoor & Adventure Equipment: Wide-temperature AA LiFePO4 batteries (-45℃~70℃) with IP69K waterproof/dustproof rating, suitable for GPS trackers, ruggedized portable lighting, and solar-powered outdoor gear. Our factory’s multi-factor environmental testing ensures stable performance in deserts, polar regions, and coastal areas—supplying 3.5 million units annually to outdoor brands.

Precision Medical Devices: ISO 13485/ISO 10993-certified AA LiFePO4 batteries with sterile production processes, antibacterial casings, and ±0.01V voltage precision, used in blood glucose monitors, portable nebulizers, and wearable medical sensors. We provide customized production schedules and on-site GMP audits for medical clients—supplying 1.5 million units annually.

Intelligent Green Manufacturing: AI-integrated production lines + carbon-neutral operations (100% renewable energy, 98% wastewater reuse, 90% material recycling) align with global ESG standards.

AA LiFePO4 Specialization: Exclusive focus on 14500-format batteries, with all processes optimized for this specification—no generic battery production.

Superior Performance Metrics: 3000+ cycle life, -45℃~70℃ temperature range, 3000mAh maximum capacity, and 0.02% defect rate (industry average 0.5%).

Rapid Customization Capability: 7–12 day prototyping, MOQ 700 units, and 20+ customizable parameters to meet niche application needs.

Global Supply Chain Integration: Dual coastal bases + regional distribution centers in Europe, North America, and Asia, enabling 3–7 day local delivery.

Comprehensive Compliance: Full certification portfolio for industrial, IoT, and medical applications, simplifying client market access.

Bulk Supply Partnership: Long-term agreements with volume-based pricing, safety stock guarantees, and just-in-time delivery to support client production lines.

Custom Development Collaboration: Joint R&D for scenario-specific AA LiFePO4 solutions, including material selection, performance optimization, and pilot production validation.

OEM/ODM Partnership: End-to-end services covering product design, tooling development, mass production, and branding—adapting to client technical specifications and market strategies.

Co-Development Program: Collaborative innovation for next-generation AA LiFePO4 technologies, sharing R&D resources and intellectual property rights.

We cordially invite you to explore our intelligent green factory (virtual reality tour available) to witness AA LiFePO4 production processes, R&D facilities, and quality control systems. Contact us today for:

Free samples of AA LiFePO4 batteries (up to 10 units per client)

Detailed technical datasheets and green manufacturing reports

Tailored quotations for bulk/long-term production contracts

Custom AA LiFePO4 solution design (capacity, discharge rate, environmental adaptation)

Partner with the leading AA LiFePO4 battery factory—power your innovations with safe, durable, and sustainable 14500-format batteries!

Top 3.2V 26650 Rechargeable Battery Supplier

Reliable 26650 Rechargeable Battery Supplier | Expert Lithium Cells

Efficient 3.2V 26650 Rechargeable Battery Factory

26650 Rechargeable Battery Factory: Manufacturing Benefits

Top 3.2V 26650 Battery Manufacturer: Custom Solutions

Top 26650 Rechargeable Battery Manufacturers

Top 10440 Cylindrical Battery Supplier - Choose Wisely

Reliable 3.2V 10440 Battery Supplier Guide