We are a professional AAA cylindrical battery factory exclusively dedicated to 10440-format 3.2V LiFePO4 (lithium iron phosphate) battery production. As a 实体 manufacturing base with independent R&D and full-cycle production capabilities, our factory integrates precision manufacturing, smart quality control, and scalable supply—delivering industrial-grade reliable AAA cylindrical batteries for global B2B clients in industrial control, IoT, medical devices, and outdoor electronics. Our core strength lies in factory-specific advantages: specialized production lines, strict on-site quality management, and compliant large-scale manufacturing.

Dual Production Bases: Two coastal-located factories (total area 50,000㎡) with convenient logistics access to major ports. Factory 1 focuses on mass production (20 automated lines) while Factory 2 specializes in custom R&D and small-batch production (5 pilot lines).

Class 1000 Clean Workshops: 8 dust-free production areas (12,000㎡) optimized for AAA cylindrical battery assembly, with constant temperature (23±2℃) and humidity (40±5%) control to ensure LiFePO4 material stability.

Integrated Production Flow: Streamlined layout covering electrode preparation → precision winding → electrolyte injection → laser sealing → formation aging → quality testing → packaging, minimizing material transfer and ensuring production efficiency.

Warehousing & Logistics: 3,000㎡ temperature-controlled raw material warehouse (for LiFePO4 cathodes and graphite anodes) and 5,000㎡ finished product warehouse, equipped with automated storage systems (ASS) for 30 million units annual storage capacity.

10440-Format Dedicated Lines: 25 automated production lines exclusively for AAA cylindrical batteries, with 3.2V-specific process optimization. Key equipment includes:

Precision winding machines (tension control ±0.1N) for uniform electrode alignment in cylindrical structure

Laser welding systems (sealing leak rate ≤1×10⁻⁶ Pa·m³/s) for hermetic cap sealing

Temperature-controlled electrolyte injection machines (dosage accuracy ±0.01ml)

Automated aging ovens (72-hour constant-voltage aging for 3.2V cells)

Smart Production Control: MES (Manufacturing Execution System) fully deployed across all lines, real-time monitoring of 120+ production parameters (electrode thickness, voltage precision, sealing tightness) with 0.1s data sampling frequency.

Scalable Capacity: Annual production capacity of 30 million AAA cylindrical batteries, supporting:

Bulk orders: 100,000+ units/month (lead time 7–15 days)

Custom batches: MOQ 500 units (lead time 2–4 weeks via pilot lines)

Capacity expansion: 4 additional lines under construction (increasing output by 4.8 million units/year)

Dedicated Testing Center: 800㎡ on-site laboratory with 30+ specialized equipment for AAA cylindrical batteries:

Voltage precision testers (±0.001V accuracy) for 3.2V consistency checks

Cylindrical shell roundness gauges (tolerance ±0.02mm)

Cycle life testing chambers (2000+ cycles simulation)

Extreme environment test equipment (-40℃ to 60℃ temperature range, vibration 10–2000Hz)

UN38.3 compliance testing setups (impact, thermal abuse, short-circuit)

Full-Cycle Inspection Process:

Incoming material inspection (LiFePO4 purity ≥99.5% verification)

In-line 100% inspection (winding uniformity, sealing quality)

Post-production sampling (5% batch testing for 3.2V discharge performance)

Aging screening (72-hour 3.2V constant-voltage test for all finished cells)

Traceability System: Unique QR code for each battery, linking to factory production records (raw material batch, production line, test data, inspector ID) accessible via client portal.

High-purity LiFePO4 cathodes (≥99.5%) and modified graphite anodes, tailored for 3.2V nominal voltage

Electrode ratio optimization (1:1.05 cathode/anode) for stable 3.2V discharge curves (100% to 0% SOC)

10440 cylindrical format maximizing energy density (1000–1500mAh) with compact footprint

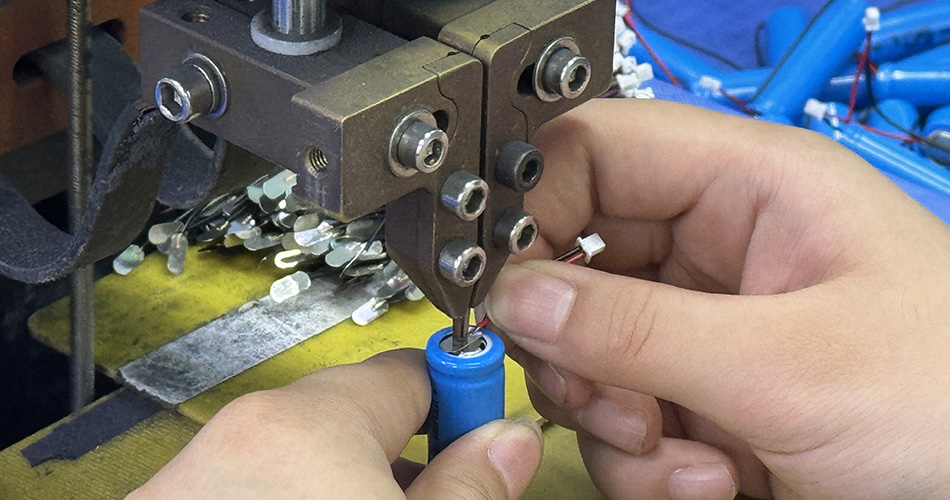

Precision Winding: Customized equipment for AAA cylindrical structure, ensuring uniform electrode alignment to minimize internal resistance

Hermetic Laser Sealing: Factory-calibrated welding parameters for airtight sealing, preventing electrolyte leakage

Gradient Electrolyte Injection: Temperature-controlled (25±2℃) process for uniform distribution, reducing self-discharge (≤2%/year at 25℃)

Anti-Corrosion Shell Treatment: 304 stainless steel stamping + nickel-plated coating (in-house processing line)

Dedicated pilot production line in Factory 2 for new product development

Rapid prototyping capability (2–4 weeks) for customized 3.2V solutions (capacity, discharge rate, packaging)

12+ patents in LiFePO4 cylindrical battery design and manufacturing

Industrial Control: ±0.01V voltage stability, vibration resistance (10–2000Hz) – 5 million units supplied annually to automation brands

IoT Devices: 0.05C ultra-low discharge rate, 5–10 year service life – qualified supplier for smart meter manufacturers

Medical Equipment: ISO 13485 certified production line, sterile-grade process – trusted by 15+ global medical device brands

Outdoor Electronics: IP67 waterproofing, -40℃ low-temperature performance – factory-tested for extreme environments

Specialization: Exclusive focus on 3.2V AAA cylindrical LiFePO4 batteries – no generic production, all equipment/facilities optimized for this format

Scalability: 30 million units/year capacity + expandable lines, ensuring stable supply for growing client needs

Quality Assurance: On-site laboratory + full-cycle inspection + MES smart control – 0.03% defect rate (factory-tested data)

Compliance: Factory certified with ISO 9001, ISO 14001, ISO 13485, UL 1642 – full compliance with global standards

Transparency: Client factory visits welcome, real-time production monitoring via MES portal

Sustainability: 100% renewable energy powering production, recyclable packaging, wastewater treatment system (reuse rate 95%)

Environmental Management: Wastewater treatment plant (daily capacity 500m³), dust collection systems, electrolyte recycling program

Safety Certifications: UN38.3, UL 1642, CE, RoHS, REACH, EU EPR compliance

Social Responsibility: Labor compliance (ISO 45001), anti-child labor policy, employee training programs

We invite you to visit our AAA cylindrical battery factory to inspect production lines, quality control processes, and R&D facilities. Contact us today for factory sample requests, technical datasheets, or bulk production quotations. Let’s build a reliable partnership based on transparent manufacturing and high-quality 3.2V AAA cylindrical batteries.

Top 3.2V 26650 Rechargeable Battery Supplier

Reliable 26650 Rechargeable Battery Supplier | Expert Lithium Cells

Efficient 3.2V 26650 Rechargeable Battery Factory

26650 Rechargeable Battery Factory: Manufacturing Benefits

Top 3.2V 26650 Battery Manufacturer: Custom Solutions

Top 26650 Rechargeable Battery Manufacturers

Top 10440 Cylindrical Battery Supplier - Choose Wisely

Reliable 3.2V 10440 Battery Supplier Guide